Specialized technological implementation

Our engineering department together with the manufacturing and maintenance team specialize in the following technologies with a high degree of experience and a pragmatic vision of solving and adapting to changes in different processes.

Pump and treat

The pumping and treatment of contaminated aquifers makes it possible to extract contaminated water through the use of one or more extraction wells. Treatment is applied to the pumped water to reduce its pollutant load. The treated water can later be reinjected into the subsoil. We also offer the option to create hydraulic barriers that involves removing large volumes of groundwater in an automated manner to prevent contaminants from expanding. This method of isolation is combined with others for treatment and recovery. The advantages of this treatment: it is applicable to large areas, the only option for deep affectations, suitable for LNAPL and DNAPL, and a wide range of inorganic and organic contaminants.

High vacuum / Dual Phase

High vacuum extraction is an 'in situ' decontamination system for aquifers affected by a phase free of light contaminants (LNAPL) and contaminated water. It is also known as Multiphase extraction (MPE, Multi Phase extraction) or Dual Phase Extraction (DPE), because it allows the liquid phase and gas phase to be extracted simultaneously. This technique is highly effective in areas with the presence of free phase, as well as for the extraction of groundwater in poorly permeable media and suitable for facilities in use, generating little interference with the daily activity of the facility.

Venting / Sparging

Sparging or 'air bubbling' is an in situ remediation technology that reduces the concentrations of volatile components in petroleum products that adsorb to soils and dissolve in groundwater. This technology involves the injection of pollutant-free air into the saturated zone of the subsoil, which allows a phase transfer of hydrocarbons from a dissolved state to a vapor phase. The air is then vented through the unsaturated zone.

Air sparging is most often used in conjunction with Soil Vapor Extraction (SVE), but can also be used with other reclamation technologies. When bubbling air is combined with SVE, the SVE system creates negative pressure in the unsaturated zone through a series of extraction wells to control vapor plume migration. This combined system is called AS / SVE. Chapter II offers a detailed analysis of small and vulnerable economies.

Air bubbling is less applicable to diesel fuel and kerosene. Proper use of air sparging may require it to be combined with other repair methods (e.g. SVE or pump and treat)

Physical-chemical treatment

The contaminated water chemical physical treatment is intended by the addition of certain chemicals altering the physical state of the substances which remain indefinitely stably to convert them into particles capable of sedimentation separation / flotation. At Envirotecnics we design, size and manufacture the facilities for physical-chemical treatment. We offer Jar Test pilot type tests to optimize the efficiency of these processes to reduce operating costs.

Filtration

We offer a wide range of filters and filtration mechanisms such as mechanical filters, rotary sieves, sand filters, and active carbon filters among others. We are specialized in activated carbon filtration systems and we have a wide range of specific types of activated carbon depending on the pollutant to be removed. We supply filters made of steel, stainless steel or plastic depending on the specific requirements of each project / application.

Membranes

En el ámbito del tratamiento de aguas residuales/ contaminadas, la tecnología de membranas ofrece posibilidades de alcanzar muy altos rendimientos de depuración/ In the field of waste / contaminated water treatment, membrane technology offers possibilities to achieve very high purification / decontamination performances. Depending on the requirements of the project can be selected between membranes micro-, ultra- and nanofiltration or reverse osmosis also. We have pilot teams to carry out the corresponding tests in order to choose the best option for each application.

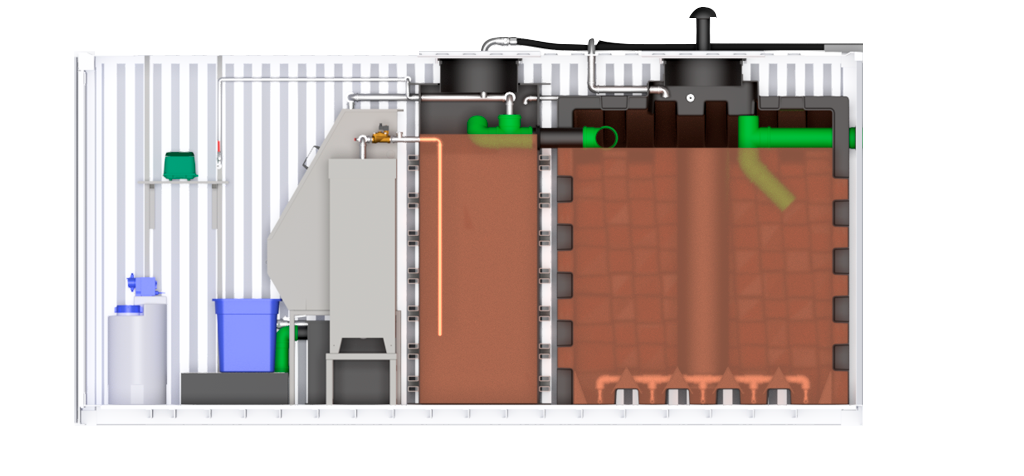

Biological treatments

We are the exclusive representative in Spain of the German company Delphin Water Systems , manufacturer of biological treatment plants with fixed-bed technology. We offer the supply and installation of small wastewater treatment plants (up to 50 inhabitants with CE certificate according to EN 12566-3), compact treatment plants for 60 to 640 inhabitants and treatment plants in maritime containers, completely assembled with a capacity of up to 4000 inhabitants. In addition, we offer facilities for tertiary treatment for a high elimination of nutrients and the sanitization of treated water with the aim of its reuse according to the legal requirements in Spain. On the other hand, we offer biological treatments in the field of soil decontamination.