Tailor-made projects

At Envirotecnics we offer our clients the experience and knowledge of a cross-disciplinary professional team for developing their projects in a personalised way. Our services cover the whole range from initial environmental technical consultancy through to the industrial engineering involved in building the project, from the logic of operation through to the 3D layouts.

Technical consultancy

We start by exchanging fundamental information with our clients. They will present the specific details, requirements and goals for the project. From this information we will draw up a technical proposal with the basic features: treatment type, equipment sizes and so on, together with sketches and generic layouts.

Through our consultancy we find out an optimal solution for each project by putting together the information we receive from our clients with our team’s experience and professional know-how.

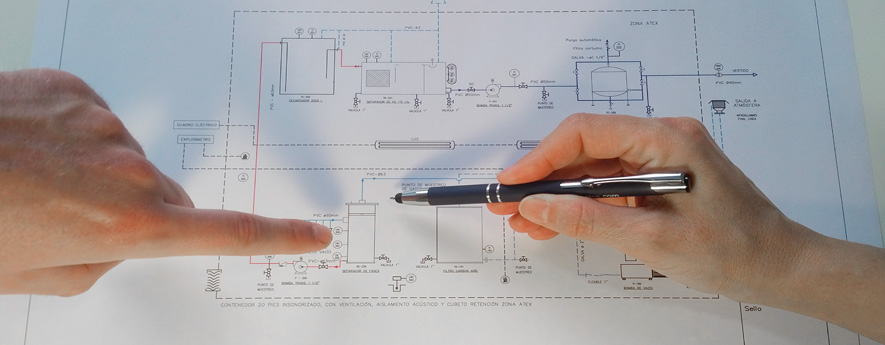

Piping & Instrumentation Diagram

Once the requirements and goals of a project have been identified, a Piping & Instrumentation Diagram (P&ID) is drawn up. The diagram lays out the basic details of the configuration for a treatment system suited to the application: its main components and control systems. This is the foundation outlining the client's requirements and goals, and the construction project will be finely designed and executed according to it.

Planos 2D

Once the technical concept and main components of the treatment system have been agreed on with the client, 2D drawings of the equipment making up the treatment unit are produced. Thanks to these drawings the functionality of the treatment system can be evaluated initially.

Planos 3D

After defining and sizing each component in the system, detailed layouts and a 3D layout are drawn up for reviewing each component in detail. The layouts are then shown to our client for approval. Immediately after, the treatment system is assembled.

Technical manual

We produce a thorough technical manual for each treatment system we manufacture. This document is unique to that particular system, and it contains all the relevant information on the installation, commissioning and operation of the treatment system.

Among the details in the document are power, flow rates, type, manufacturer and serial number of each piece of equipment, as well as safety and maintenance information.