Turnkey services

We are aware of the environmental challenges that our clients face on a daily basis. We are flexible, pragmatic, and innovative in the provision of solutions.

Manufacturing and maintenance

Our highly specialised team follow thorough procedures for the design, manufacture and maintenance of our Treatment Systems in our facilities. Clients can thus customise their treatment systems according to their needs.

Our systems fully conform to the risk and safety assessments required by the regulations of the sites to be treated. Units can be CE and ATEX certified on request.

Our lines of work are:

- The manufacture of customised equipment, according to the needs of the client.

- The assembly of the components as per the build plans and layouts and P&ID.

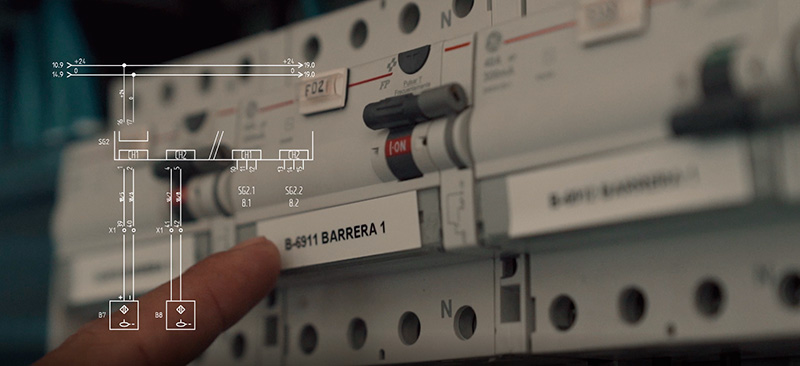

- The manufacture of electrical cabinets, and the programming of controllers (PLC, HMI and SCADA).

- The execution of FATs (Factory Acceptance Tests). Those are quality controls to which we subject all the equipment we produce in our facilities. With these we fully verify the units and guarantee their compliance with technical manufacturing specifications.

- We build and maintain our equipment following the technical specifications that are needed to comply with the safety regulations in place.

- We have a team of highly qualified technicians experienced in the manufacture and maintenance of treatment systems.

Turnkey

We offer an all-round process, from the very first contact made with our client. This makes us leaders in the design and execution of projects.

- Technical proposal.

- P&ID, layouts and animations.

- Manufacturing and quality controls.

- Door-to-door logistics.

- Commissioning and maintenance of each system.

We closely follow each project as outlined, making best use of resources.

Safety control and prevention

We base our safety policy on prevention. That is why we have a continuous safety training programme in place for all our staff.

- We have a safety plan in place we closely follow in each of our lines of work, in particular unit design, commissioning and maintenance.

- We guarantee the maintenance we perform on our equipment fully complies with current safety standards.

Emergency breakdowns

We offer a rapid response to emergencies. Our systems are remotely managed. This allows us to respond immediately in the event of a stoppage, a breakdown, or an environmental incident affecting normal operation of systems.

Remote management

- Development and customisation of PLC software as well as programs for operator interface screens and system control.

- Development of HMI applications with the display of process and equipment parameters within an interface.

- Employment of SCADA software and implementation of remote-control interfaces in our systems for monitoring and data acquisition purposes.

Rental

We rent out units to clients for significant savings and maximisation of profitability on short term projects. Benefits are:

- Adaptation, installation and maintenance by our specialised technicians.

- Guaranteed operation, certifiable calibration documentation, all on equipment that has been calibrated and tested. User manuals. Training and round the clock assistance.

- Coordination of logistics to ensure remote locations are reached quickly and urgently if needed.

Pilot Trials

With pilot trials we can extract and treat large amounts of volatile products from the subsoil.

We have four mobile pilot units for Dual Phase Extraction and Ventilation trials. The units can perform periodic vacuum checks and extraction of air and water, and are equipped with a phase separator and an activated carbon filter. This allows for both water and air to be treated during the process.

Other instruments can also be added on request.

Our technicians have extensive experience in the deployment and execution of these trials.