Description

Características

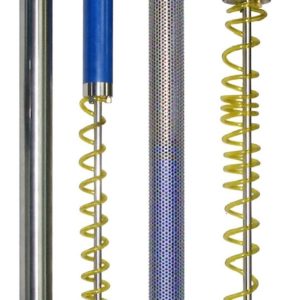

The clamping cable is made of adjustable stainless steel and includes a silver ring. The collecting container is made of PVC / polyethylene. The membrane is 100mm long. Absorbs on contact with fuel. Resistant to immersion in water. Stainless steel base with discharge valve made of brass. It can be emptied in the field.

They require no power or moving parts.

Viscosity

LNAPL fluids have chemical and physical characteristics that can affect Oilwick recovery. One variable is viscosity. In most cases, Oilwick can efficiently recover oils of up to approximately 75-100 centistokes *. Have in mind that the bottom hole temperature must be close to that of the analysed viscosity. Also note that suspended sediments or heavier coagulation components can delay Oilwick’s recovery over time.

The viscosity of gear oil would be a typical upper physical limit for Oilwick recovery.

Oilwick skimmers can tolerate a wider range of LNAPL physical and chemical characteristics. However, the Oilwick is not as easy to operate as the RSS membrane skimmer. Both the RSS membrane and the Oilwick skimmers should be considered non-floating as they are filled with hydrocarbons. The standard RSS membrane skimmer is tolerant of 200mm liquid level changes within its well while retrieving LNAPL. RSS membrane skimmers will repel water at even greater fluid level fluctuations, while the Oilwick can absorb water if the LNAPL fluid / water interface is raised above the slotted collection section, approximately 80mm for narrow layers of LNAPL.

The Oilwick for 2 “wells is intended for viscous or uncharacterized hydrocarbons other than gasoline and diesel.

They are best deployed where fluid levels fluctuate less than 80mm between collection sessions.

Standard skimmer tanks are made of PVC, therefore, aggressive chemicals that attack PVC must be taken into account.

Tips: When the viscosity / density / chemistry of hydrocarbons resembles oil that no longer pours like clear honey, we recommend Oilwick.

*. cST is the kinematic viscosity (centistokes, cSt).

Funcionamiento

The Oilwick passive skimmer must be installed at the interface between water and product. The membrane must be positioned at the level of the interface; for this, it is helpful to use a biphasic probe for locating and estimating its thickness. The suspension cable must touch the bottom of the tank / well.

The oleophilic membrane (located under the slotted cylinder at the top of the skimmer) allows the product to pass through (LNAPL). The product is accumulated in the reserve chamber of the skimmer by gravity. As the tank fills up, the equipment will submerge to where we have installed the cable. Once the tank is full, the tank must be removed in order to recover the retained product.

| Product | Tank capacity | Diameter |

| OILWICK25 | 0.35 L | 4.25 cm |

| OILWICK50 | 1.0 L | 6 cm |

| OILWICK75 | 2.25 L | 9 cm |

IMPORTANT

To dissipate any static electricity during emptying, firmly connect a ground wire between the lower brass valve and its container before opening the valve, or make sure the valve or metal skimmer base is in constant contact with its receiving container.

Aplicaciones

These skimmers are used for the recovery of chlorinated, halogenated hydrocarbons, solvents. Unlike other skimmers these offer the possibility of absorbing denser product.

Excellent for the recovery of small amounts of free product or in low flow of hydrocarbons. Also, for pollutant reduction calculations.